Liadain Aiken Knitwear

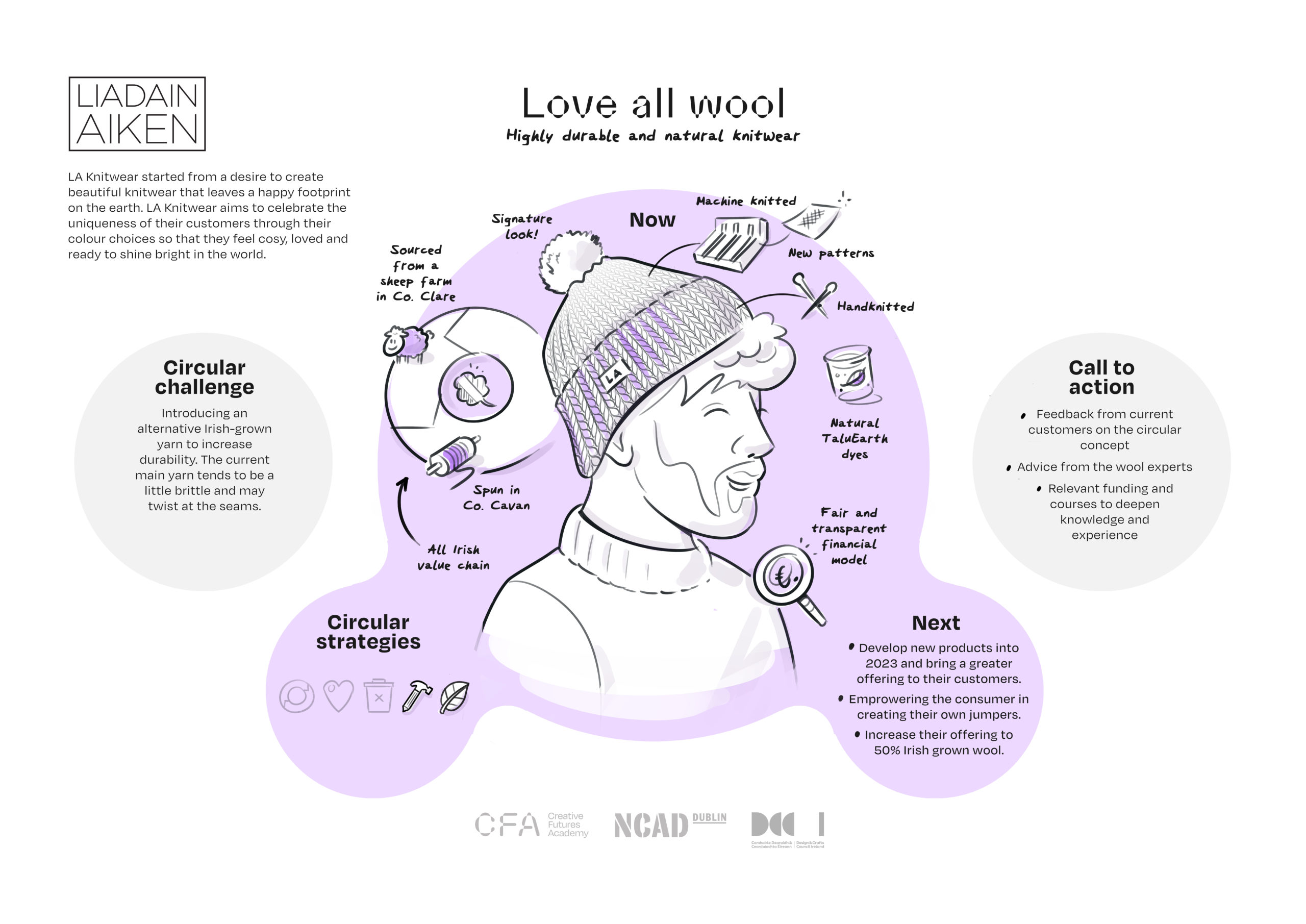

Liadain Aiken Knitwear started from a desire to create beautiful knitwear that leaves a happy footprint on the earth. Liadain Aiken Knitwear aims to celebrate the uniqueness of their customers through their colour choices so that they feel cosy, loved and ready to shine bright in the world.

Love All Knitwear

The circular challenge

Liadain Aiken Knitwear identified that their main circular challenge was the durability of their yarns – specifically in relation to their jumpers. The wool in question is primarily a merino wool from New Zealand or Australia, which is spun by an Irish company. They concluded that for those customers who are hard-wearing on their clothes, the main yarn tends to be a little brittle and may twist at the seams.

This prompted LA Knitwear to use the prototyping opportunity to further the introduction of Irish-grown yarn into their offering. This utilises the full potential of a highly durable, local, renewable resource, reduces air miles and mitigates any question of whether the merino sheep in their extended value chain have been subject to mulesing.

The circular design strategy:

- Design for Physical Durability

- Design from Safe, Renewable or Recycled Materials

The NOW solution: What circular solution was prototyped and what are the companies short-term circular goals?

LA Knitwear’s circular concept is entitled ‘Love All Wool’ and aims to create highly durable and natural knitwear products, with an end-to-end Irish supply chain.

As part of this concept, they are currently working with wool that was sourced from a sheep farm in Co. Clare last year, and subsequently spun in Portugal. Now, they are furthering their nearshoring efforts, and spinning this year’s wool with a mill in Co. Cavan – thereby building an all-Irish value chain.

To reduce impact in the dying process and ensure the products are biodegradable at eventual their end-of-life, LA Knitwear are collaborating with Natural Dye expert Malú from a fellow pilot company TalúEarth to dye some of the yarn. To create the final products, they will combine machine knitting on hand-driven knitting machines, with handknitting – the body of the garment will be made in undyed wool on a chunky knitting machine and the ribs will be handknitted with the naturally dyed wool, to create their signature look of playful colours on the ribs.

What were the main hurdles and lessons learnt from your prototyping phase?

One of the key hurdles that LA Knitwear encountered whilst prototyping their circular product was in adapting their usual production process to accommodate the new Irish wool – from returning to working with a chunky knitting machine, to developing new patterns, to handknitting the ribs. Handknitting is a time intensive process, and the first batch of naturally dyed yarn transfers dye onto the maker’s hands – an issue which needs to be further explored and addressed.

Another challenge is in calculating and developing a fair and transparent financial model that factors in all the various costs; from paying the farmer for the regeneratively farmed wool, to spinning the wool in Ireland, to dying the wool with natural dyes, to finally knitting the final product.

The NEXT solution: What are your bigger / longer-term circular goals for your brand?

LA Knitwear’s long-term circular solution is to continue to develop new products into 2023 and bring a greater offering to their customers. They are also interested in expanding on their cottage industry roots, and empowering the consumer in creating their own jumpers – perhaps through the development of hand-knitting kits.

Their ultimate aim is to increase their offering to 50% Irish grown wool in the next few years. In order to do so, they recognise the need to drive both demand and supply of Irish wool, nationally. Therefore, they hope to work with other sheep farmers from across Ireland, to explore how they can collaboratively develop more Irish grown yarn from various breeds and whether they can garner support from the Irish government to start more scouring and spinning facilities in Ireland.

Projected future impact: What is the expected positive impact - environmental, economic, social - from your longer term circular solution.

LA Knitwear recognises that the positive impact of using more Irish grown wool is somewhat vast and immeasurable, given its relative nascency.

For their own company, they anticipate that the shift towards Irish wool will increase their customers’ connection to their clothes, since they will have greater transparency over the LA Knitwear supply chain, and know where the wool came from. This connection will hopefully have an immediate knock on effect and encourage customers to change how they choose and use their clothing.

For the wider industry and in the longer term, LA Knitwear hopes that by advocating and representing the demand for Irish wool, they will encourage more Irish farmers to reassess their current practices of leaving wool in a field to rot or burning it. They hope that more farmers will be encouraged to adopt regenerative farming methods, which are much better for the health of the sheep, the land and the regeneration of soil health, and in turn, can increase the value of their fleece. Increasing the demand for, and quality of, Irish wool might also encourage more facilities in Ireland to process the fibres into yarn or other products, and create more industry jobs along this new value chain.

What questions or uncertainties are you facing right now in terms of your circular development?

- What products can I design that suits the Irish grown wool texture?

- Will my customers like the new products and the texture of the wool?

- Will the cost of the new garments be at a good price point?

- Will I be able to get raw wool processed into yarn easily in Ireland?

- Will the quality be good?

Call to Action:

To move from prototype to pilot, LA Knitwear are looking for the following supports:

- Feedback from my current customers on the circular concept, and the look and feel of the prototypes

- Advice from the wool mill and other wool industry experts on processing yarn (skirting, sorting, scouring, spinning) and improving the quality (appropriate ply, twist depending on wool type)

- Financial support to fund the development of an Irish grown fleece-to wool-to garment supply chain.

- Relevant funding supports and courses to deepen knowledge and experience in the following areas: 1.DIY wool processing & spinning on a wheel – is this yarn only suitable for hand knitting. 2 professional mills with case study visits to the UK, Spain, Portugal and others. 3 Regenerative farming & small scale sheep farming